Stationary detector for VOCs

|

|

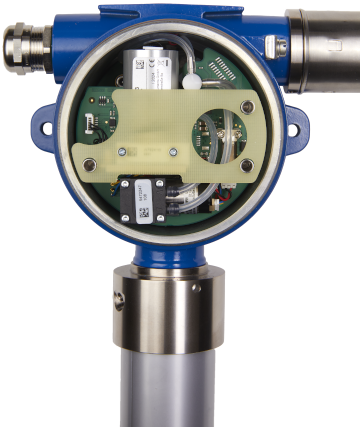

The Stationary Photoionisation Detector SPID3 is a continuously measuring detector for volatile organic compounds (VOCs) with an ionisation potential < 10.6 eV. The use of new technologies for the light source and the sensor enables a high stability of the measurement and longer maintenance intervals. Automatic purging and automatic calibration are controlled via an integrated activated carbon filter and the sampling circuit. The device is designed for operation in potentially explosive atmospheres. |

Product Specification

Extended measuring rangeNewA new sensor unit allows three staggered measuring ranges from 20 ppm up to 5 000 ppm (isobutene) with high resolution at low concentrations. |

Easy user interfaceA graphic display with intuitive user guidance, clear text instructions and step-by-step configuration support the ease of use. |

High performance PID lampThe ionisation source is a hollow cathode lamp with an energy of 10.6 eV. The Ceramic Discharge Channel ensures high stability and a longer lifetime of up to 15 000 hours and more. |

Extended service intervalThe high stability of the lamp and the special design of the sensor in conjunction with automatic feeding of pollutant-free air through an activated carbon filter results in longer maintenance intervals. |

Simple calibrationEven in heavy environment, only one calibration gas is required for the simple menu driven two-point calibration. The applied active carbon filter provides the zero point. |

Automatic fresh air setupFor testing and adjusting the zero-point, pollutant-free air is applied via the activated carbon filter periodically through the gas path. |

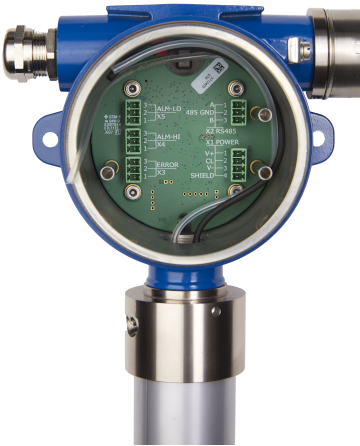

Flexible connectionsA wide range of supply voltage, a configurable current loop output, alarm and error relays, a RS485 interface with MODBUS and Hart protocol facilitate integration into your system. |

Temperature / humidity compensationThe integrated humidity / temperature sensor measures the physical environment data in addition to the sensor signal and compensates their influence on the measuring result. |

IECEx / ATEX certificationThe SPID3 fulfils the requirements for use in potentially explosive atmospheres and has the appropriate certifications in accordance with ATEX and IECEx. |

Technical Data

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||