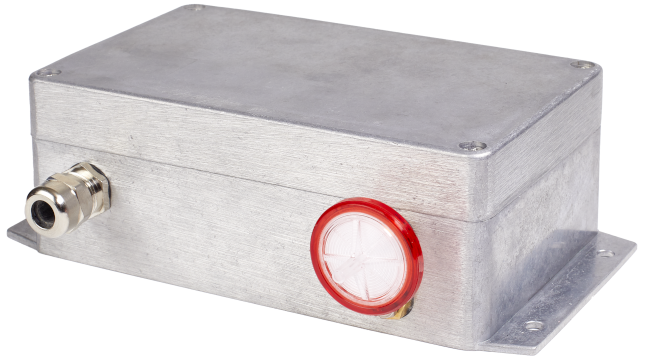

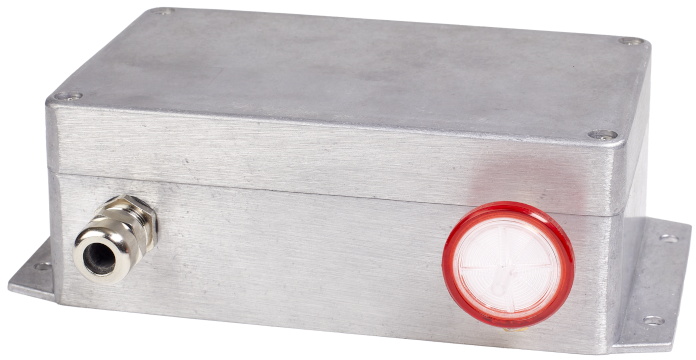

Smart Photoionization Detector Module PIDS3

|

|

The Smart Photoionization Module PIDS3 is an OEM module to detect volatile organic compounds with an ionization potential < 10.6eV. With its built-in electronics and microcontroller as well as a combined humidity/temperature sensor, it provides a flexible and easy to use adaptation into your measurement system. The module comes with a built-in linearization and temperature/humidity compensation. Built-in barometric pressure sensors offer later compensation and gas flow monitoring. The RS485 interface allows additional flexibility to choose the right interface for industrial and laboratory applications. The optional analogue 4 … 20 mA output represents the linearized and compensated concentration value in different scaling. The module is available in different measurement ranges, with optional included pump and 4 … 20 mA output and MODBUS. |

Product Specification

New

|

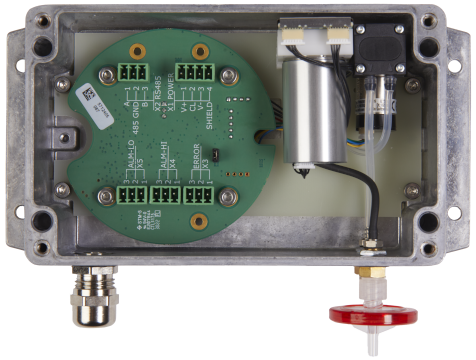

High performance PID lampThe ionization source is a high stable hollow cathode lamp with an energy of 10.6 eV. With its ceramic discharge channel, the stability is improved and a longer service life of up to 15 000 hours and more will achieved. |

Wide power supply rangeSince the power supply of the PID lamp is integrated, the unit works with a wide input range power supply. |

Flexible connectionsThe galvanic isolated RS485 interface supports reading measurement, diagnostic results, remote calibration and configuration. The RS485 interface allows additional flexibility to choose the right interface for industrial and laboratory applications. The optional analog 4 .. 20 mA output represents the linearized and compensated concentration value in different scaling.

|

Temperature / humidity compensationThe integrated humidity / temperature sensor measures in addition to the sensor signal the physical environment data and compensates their influence on the measuring result. |

Barometric pressureOne integrated barometric pressure sensor measures continuously at the gas inlet of the measurement chamber. |

Signal processingA microcontroller handles the measurement and control functions, performs all calculations and provides the result. There is no knowledge of the particular operation of the PID sensors required. |

Gas flow monitoringThe integrated pressure sensors measures continuously the pressure drop over the measurement chamber do ensure proper flow. (a version with integrated pump is available) |

Technical Data

|

|||||||||||||||||||||||||||||||||||||||||||||