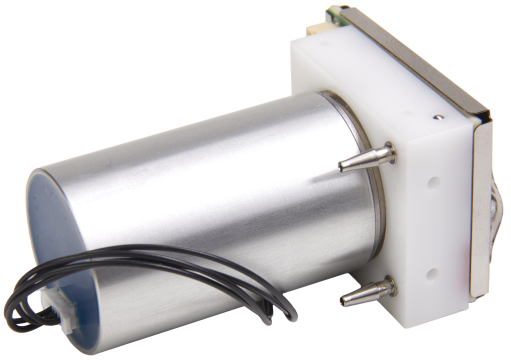

Precise detection of volatile organic compounds integrated in your own product

|

|

The PIM CPN photoionization detector module is an OEM module for detecting volatile organic compounds with an ionization potential of 10.6 eV in the standard version (10.0 eV and 11.8 eV optionally available). With its electronics and microcontroller as well as the combined humidity/temperature sensor, it offers flexible and easy-to-use customization to your measuring system. The module has built-in linearization and temperature/humidity compensation as well as a digital interface. The measuring chamber is equipped with a barometric sensor and a flow sensor for subsequent compensation and gas flow monitoring. |

Product Specification

Neu

|

High performance PID lampThe ionization source is a high stable hollow cathode lamp with an energy of 10.6 eV. With its ceramic discharge channel, the stability is improved and a longer service life of up to 15 000 hours and more will achieved. The 11,8eV lamp has a service life of 4000 hours beginning from delivery.

|

Single low volt power supplySince the high voltage power supply of the PID lamp is integrated, the unit works with a single low voltage power supply. |

Temperature / humidity compensationThe integrated humidity / temperature sensor measures in addition to the sensor signal the physical environment data and compensates their influence on the measuring result.

|

Easy connectionOnly one electrical plug with power and communication is needed to connect to the module.

|

Barometric pressureOne integrated barometric pressure sensor measures continuously at the gas inlet of the measurement chamber.

|

Signal processingA micro controller handles the measurement and control functions, performs all calculations and provides the final result in digital form. There is no knowledge of the particular operation of the PID sensors required. The unit is connected via a simple UART interface or I2C to target system. |

Gas flow monitoringThe integrated pressure sensors measures continuously the pressure drop over the measurement chamber do ensure proper flow. |

Technical Data

|

|||||||||||||||||||||||||||||||||||